Liquid Droplet Trajectories: Harnessing Sound to Measure the Unseen

The motivation of this research project

During my community services, I noticed a welder father with persistently red eyes, a common condition in his trade. This resonated deeply with my grandfather’s struggle with an undiagnosed dry eye syndrome, leading me to investigate a diagnostic method. However, I discovered that current clinical methods require fluid samples too large for practical tear collection. Drawing inspiration from an unexpected source—a childhood memory of stretching liquid—I conceived a novel solution. I am now developing a sensitive device that uses acoustic waves to measure viscosity with a minute droplet, aiming to translate a personal insight from the community into a tangible tool for better ocular health.

Abstract

Dry eye disease is a common chronic condition affecting the ocular surface, for which tear viscosity measurement plays a vital role in both diagnosis and management. However, the characteristically low viscosity and ultra-small volume of tear fluid (typically only 4–5 µL) present considerable challenges for accurate viscosity assessment, which existing techniques are unable to address adequately.

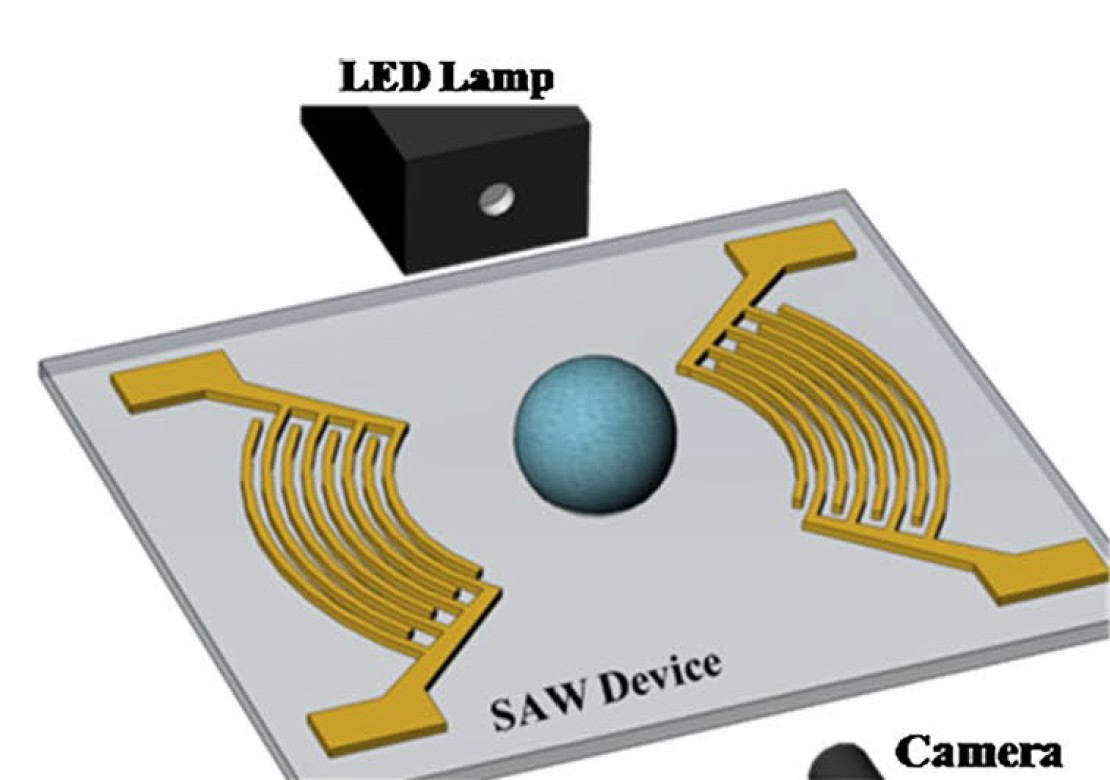

In this study, a novel method was proposed and demonstrated for measuring the viscosity, this unseen property, of low-viscosity fluids by harnessing sound waves to control liquid droplet trajectories. Focused interdigital transducers were designed and fabricated to generate surface acoustic waves (SAWs), which induce an upward elongation of a sessile droplet positioned at the focal point. Through systematic experimental observation of droplet dynamics, optimal parameters for effective SAW generation were identified: a frequency of 18.41 MHz, a pulse length of 2 ms, a pulse interval of 2 s, and a peak-to-peak voltage of 165 mV. Under these conditions, jetting droplet velocities ranged from 0.35 m/s to 0.77 m/s, enabling the droplet to reach a glass plate positioned 3 mm above and form a stable liquid bridge.

A series of fluids was tested, including water and glycerol-water solutions at volume concentrations ranging from 2% to 40%. Following bridge formation, the filament neck thinned under the influence of surface tension until eventual breakup. This transient process was captured using a high-speed camera at 20000 fps, allowing precise measurement of the filament diameter. The half-time for the filament to reduce to half its initial diameter was observed to range between 1.20 ms and 2.25 ms. The Ohnesorge number, which quantifies the relative effects of viscosity, inertia, and surface tension, was determined to lie within the range of 0.0036 to 0.014. A correlation was subsequently established between the dimensionless half-time (normalized by the Rayleigh time) and the Ohnesorge number.

Finally, the technique was applied to characterize 2-µL polyvinyl alcohol-based artificial tear samples. The measured viscosities averaged 1.65 ± 0.88 mPa·s, demonstrating the potential of this approach for practical application in the future.